Ona Mufananidzo Mukuru

Pipeline masisitimu haana kukwana pasina mavharuvhu eindasitiri.Dzinouya nehukuru hwakasiyana uye masitayera nekuti izvi zvinoda kuenderana nezvinodiwa zvakasiyana.

Mavharuvhu eindasitiri anogona kuiswa zvinoenderana nebasa rawo.Kune mavharuvhu anomira kana kutanga kuyerera kwe media;kune idzo dzinodzora painoyerera mvura.Kune mamwe anogona kusiyanisa huwandu hwemidhiya inoyerera.

Kusarudza rudzi rwakafanira rwevharuvhu kwakakosha pakushanda kwemaindasitiri.Mhando isiriyo yaizoreva kuti system yakavharwa kana system iri pasi pekuita.

Chii chiri Throttling mavharuvhu

A throttling valve inogona kuvhura, kuvhara uye kugadzirisa midhiya inoyerera.Throttling valves ndiwo mavharuvhu ekudzora.Vamwe vanhu vanoshandisa izwi rekuti "control mavharuvhu" kureva mavharuvhu anopuruzira.Chokwadi ndechekuti, pane mutsara wakasiyana unotsanangura zviviri izvi.Throttling valves ane ma discs asingangomise kana kutanga midhiya kuyerera.Aya madhisiki anogona zvakare kudzora huwandu, kudzvanywa uye tembiricha yemedia inopfuura mune chero chinzvimbo chakatemwa.

Throttling valves ichava nepamusoro-soro kune imwe mugumo uye kuderedza kuderera kune imwe mugumo.Izvi zvinovhara valve, zvichienderana nehuwandu hwekumanikidza.Mumwe muenzaniso wakadaro ndeye diaphragm valve.

Kune rumwe rutivi, mavharuvhu ekudzora anodzora kuyerera kwe media nekushandisa actuator.Haikwanise kushanda pasina imwe.

Kudzvanya uye tembiricha zvinokanganisa kuyerera kwe media saka mavharuvhu ekudzora anodzora izvi.Zvakare, mavharuvhu aya anogona kushandura kuyerera kana kumanikidza mamiriro kuti aenderane neinodiwa pombi system mamiriro.

Mupfungwa iyi, mavharuvhu ekudzora mavharuvhu akasarudzika.Izvo zviri kutaurwa, mavharuvhu ekudzora anogona throttle asi kwete ese mavharuvhu ekupuruzira ari mavharuvhu ekudzora.

Muenzaniso wakanakisa ndeye hydraulic system apo simba rekunze rinofanirwa kuburitsa vacuum kuitira kuti gasi ripinde muvharuvhu.

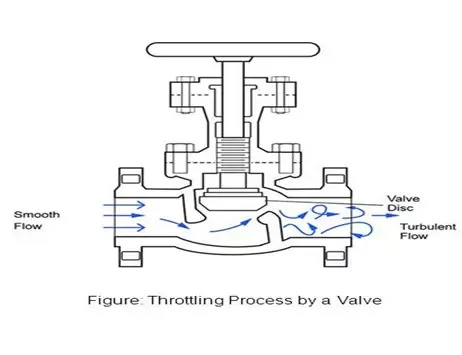

The Throttling Mechanism

Kana pombi inoshandisa throttling valve, iyo media flow rate inoshanduka.Paunenge uchivhura zvishoma kana kuvhara valve, pane kudziviswa mukuyerera kwemvura.Saka, kutonga kwevezvenhau.

Izvi zvinobva zvabatanidza nhepfenyuro muvharuvhu iya yakavhurwa zvishoma.Mamorekuru ezvenhau anotanga kudhumana.Izvi zvinogadzira kukakavara.Kupokana uku kunowedzera kudzikamisa kuyerera kwe media sezvainopfuura nemuvharuvhu.

Kuenzanisira zviri nani, funga nezvepombi sepaipi yebindu.Kubatidza, mvura inobuda yakananga kunze kwepombi pasina chinorambidzwa.Kuyerera hakuna kusimba.Zvino, funga nezvevharuvhu sechigunwe chakavhara zvishoma muromo wepoipi.

Mvura inobuda inoshanduka nhangemutange nekutsikirirwa nekuda kwekuvhara (chigunwe).Iyo yakasimba zvakanyanya kudarika mvura isati yapfuura valve.Mupfungwa huru, uku ndiko kurira.

Kuti uise izvi mupombi system, system inoda kuti gasi rinotonhorera rive painodiwa kupisa.Nevhavha inoputika panzvimbo, kupisa kwegesi kunowedzera.Izvi zvinokonzerwa nemamorekuru anokweshana paanenge achiedza kubuda muvharuvhu kuburikidza nekuvhura kudiki.

Kunobva: https://www.quora.com/What-is-the-throttling-process

Throttling Valve Applications

Kune huwandu hwakawanda hwekushandiswa kweiyo throttling mavharuvhu.Kazhinji munhu anogona kuwana throttling mavharuvhu mune anotevera maindasitiri maapplication:

● Air conditioning systems

● Firiji

● Hydraulics

● Steam applications

● Kushandiswa kwepamusoro-tembiricha

● Mishonga yemishonga

● Kushandiswa kwemakemikari

● Zvikumbiro zvekugadzirisa zvokudya

● Zvigadzirwa zvemafuta emafuta

Mavharuvhu Anogona Kushandiswa Kuridza

Haasi ese mavharuvhu ndeekupuruzira.Magadzirirwo evharuvhu ndicho chimwe chezvikonzero zvikuru nei mamwe mavharuvhu asina kukodzera throttlers.

Globe

Globe mavharuvhu ndeimwe yemhando dzakakurumbira dzemavharuvhu.Iyo globe valve inonyanya kushandiswa sevhavha inotsikisa.Izvi ndezvemhuri yemutsara inofamba valve.Globe dhisiki rinofamba richikwira kana pasi maererano nechigaro chemhete chakamira.Dhisiki rayo kana plug inodzora huwandu hwemidhiya inogona kupfuura.

Nzvimbo iri pakati pechigaro nemhete inobvumira vharuvhu yepasi kuti ishande sevharuvhu yakakura.Pane kukuvadzwa kushoma kune chigaro uye dhisiki kana plug nekuda kwekugadzirwa kwayo.

Kuganhurirwa

Nekuda kwekugadzirwa kwevharuvhu yepasi, kana ichishandiswa mu-high-pressure application, inoda otomatiki kana powered actuator kufambisa dzinde uye kuvhura vharuvhu.Kudonhedza kudonhedza uye huwandu hwekudzora kuyerera ndizvo zviviri zvinotariswa zveanoshanda throttling kugona.

Kune zvakare mukana wekudonha nekuda kwechigaro chakakanganisika sezvo ichi chinouya mukusangana kwakazara neinoyerera midhiya.Iri vharafu rinosanganawo nemhedzisiro yekudengenyeka, kunyanya kana midhiya iri gasi.

Butterfly

Butterfly mavharuvhu anoita sevhavha yegedhi.Asi, imwe yemisiyano yavo yakasiyana ndeye butterfly valve ndeyemhuri yekota-turn valve.

Simba rekunze rinoshanda pane actuator.Iyi actuator inosungirirwa kune hunde iyo inobatanidza kune disc.

Pakati pemavharuvhu akajairika, butterfly valve ndiyo inonyanya kukodzera kupuruzira.A full quarter turn anogona kuvhura kana kuvhara valve.Kuti throttling iitike, inongoda kuvhura zvishoma kuti midhiya ipfuure.

Kuganhurirwa

Imwe yezvipimo zvevhavhavhavhavha ndeyekuti disc inogara iri munzira yekuyerera kwenhau.Iyo dhisiki yese inobatwa zvakanyanya nekukukurwa.Uyewo, nekuda kwekugadzirwa uku, kuchenesa zvikamu zvemukati zvakaoma.

Kuti vharuvhu yeshavishavi ishande, kuverenga kwakakodzera kunofanirwa kuona kuyerera kwakanyanya uye kumanikidza zvinodiwa.

Gate

Ivhavhavha yegedhi ndeyemhuri yemutsara inofamba valve.Mavharuvhu egedhi ane madhisiki anokwira nekudzika kuti avhure nekuvhara mavharuvhu.Iwo anonyanya kushandiswa sekuvhura-kuvharwa-kuvharwa masevhisi.Mavharuvhu egedhi ane zvaasingakwanisi kuita semavharuvhu ekukwenya.

Muchinenge chakavharwa-aperture, throttling inoitika sezvo ichidzikamisa kuyerera kwenhau.Izvi zvinowedzera velocity yemedia painobuda muvharuvhu.

Kuganhurirwa

Iyo chete nguva yaunofanirwa kushandisa gedhi mavharuvhu ekupuruzira ndeye apo vharafu iri 90% yakavharwa.Kuivhara kunosvika 50% chete hakugone kuwana inodiwa throttling kugona.Izvo zvakaderera pakushandisa gedhi revhavha ndeyokuti velocity yevhidhiyo inogona kukanganisa nyore nyore chiso che disc.

Pamusoro pezvo, mavharuvhu emagedhi haafanire kushandiswa semavharuvhu ekupuruzira kwenguva yakareba.Dzvinyiriro inogona kubvarura chigaro chegedhi kuitira kuti valve isakwanise kuvharika zvachose.Imwe, kana yepakati iri mvura, pane vibration.Kudengenyeka uku kunogona kukanganisawo chigaro.

Pinch

Inofungidzirwa seimwe yeakareruka dhizaini, pinch valve ine yakapfava elastomer liner.Inopiniwa kuvhara uchishandisa fluid pressure.Nokudaro, zita rayo.Yemhuri yemutsara inofamba, pinch vharafu haina uremu uye iri nyore kuchengetedza.

Pinch mavharuvhu anoshanda chaizvo kana sterility uye utsanana zviri pamberi.Elastomer liner inodzivirira simbi zvikamu zvevhavha.

Dzinde rinonamira kune compressor iyo yakanyatsoiswa pamusoro pe liner.Iyo pinch valve inovhara kana compressor ichidzika kune liner.

Kugonesa kwepinch valve kunowanzo kuve pakati pe10% kusvika 95% kuyerera kwehuwandu.Kubudirira kwayo kwakanyanya kuri pa50%.Izvi zvinokonzerwa netambo yakapfava uye madziro akatsetseka.

Kuganhurirwa

Iyi vharuvhu haishande zvakanyanya kana midhiya ine zvimedu zvakapinza, kunyanya kana vharafu iri 90% yakavharwa.Izvi zvinogona kukonzera misodzi mu elastomer liner.Iyi vharafu haina kukodzera gasi midhiya, uye yakanyanya kudzvanywa uye tembiricha yekushandisa.

Diaphragm

Iyo diaphragm valve yakafanana chaizvo nepinch valve.Nekudaro, mudziyo wayo wekupuruzira ndeye elastomer diaphragm pachinzvimbo che elastomer liner.Unogona kutarisa kuti diaphragm mavharuvhu anoshanda sei muvhidhiyo iyi.

Mune pinch valve, compressor inodzikira mukati me liner uye yobva yaipinza kuti imise media kuyerera.Muvharuvhu yediaphragm, diaphragm disk inotsikirira pasi pevharuvhu kuti ivhare.

Kugadzira kwakadaro kunobvumira zvidimbu zvakakura kuti zvifambe nepakati pevhavha.Pakati peiyo yakatwasuka kuburikidza nediaphragm vharafu uye weir type diaphragm vharafu, iyo yekupedzisira iri nani yekupuruzira.

Kuganhurirwa

Kunyangwe ichigona kupa chisimbiso chisiri chekuvuza chisimbiso, mavharuvhu e diaphragm anogona kungomira zvine mwero tembiricha uye kumanikidza renji.Uyezve, haigone kushandiswa mumabasa akawanda ekuchinja.

Tsono

Ivhavhavha yetsono yakafanana neglobe valves.Panzvimbo yepasi-se disk, valve yetsono ine tsono-yakafanana disk.Izvi zvakanyanya kukodzera kune zvikumbiro zvinoda kurongeka chaiko.

Pamusoro pezvo, mavharuvhu etsono ari nani ekudzora mavharuvhu ehuwandu hudiki.Mvura inoenda mumutsara wakatwasuka asi inoshandura 900 kana vharuvhu ichivhurwa.Nekuda kweiyo 900 dhizaini, zvimwe zvikamu zvedhisiki zvinopfuura nepakuvhurwa kwechigaro kusati kwapera.Unogona kuona pinch vharuvhu 3D animation pano.

Kuganhurirwa

Mavharuvhu etsono ndeekushandiswa kwakapfava kwemaindasitiri.Izvo zviri kutaurwa, zvakakora uye viscous media hazvina kukodzera kune mavharuvhu etsono.Kuvhura kwevharuvha iyi idiki uye zvimedu zviri muslurries zvinovharirwa mumhango.

Maitiro ekusarudza Throttling Valve

Rudzi rwega rwega rwevharuvhu yekupuruzira ine zvayakanakira uye zvinogumira.Kunzwisisa chinangwa chekushandisa throttling valve nguva dzose kunoderedza sarudzo dzemhando yakarurama yevhavha inoputika.

Kukura kwevhavha

Saizi yevharuvhu yekurudyi inoreva kubvisa nyaya dzemberi dzevharuvhu.Semuenzaniso, vharuvhu yakakura kwazvo inoreva kushomeka kwesimba.Zvingangodaro, inenge iri pedyo nenzvimbo yayo yakavharwa.Izvi zvinoita kuti vharafu ive nyore kune vibrations uye kukukurwa.

Uyezve, vharafu iyo yakakura zvakanyanya inogona kunge iine mamwe mafittings sekugadzirisa kune mapaipi.Mafittings acho anodhura.

Zvinhu Zvekuvaka

Iyo valve yemuviri zvinhu chinhu chakakosha pakusarudza iyo throttling valve.Inofanira kuenderana nemhando yezvinhu zvaizopfuura.Semuenzaniso, makemikari-based media anofanirwa kupfuura nepasina-corrosive valve.Midhiya inosvika pakusvika tembiricha yepamusoro kana kudzvanywa inofanirwa kupinda mune yakasimba alloy ine mukati mekuvhara.

Actuation

Actuation inoitawo basa rakakura pakusarudza iyo chaiyo throttling valve.Mukushandiswa kwepombi, pane zviitiko zvekuti kumanikidzwa kwakasimba kuripo.A manual actuator inogona kusashanda mukuvhura kana kuvhara valve nekuda kweizvozvo.

Connections

Kuti valve yakabatanidzwa sei kune mapaipi inofanirwawo kufunga.Izvo zvakakosha kuchinjika kune iripo pombi kubatana pane iyo mapaipi anoenderana nevhavha.

Iyo inonyanya kudhura kuti ienderane nevhavha kune iripo pombi zvinodiwa.Semuenzaniso, kana pombi inopera iine flanges, vharafu inofanirawo kunge iine flanged end connections.

Industry Standards

Mitemo yeindasitiri yakakoshawo.Pane zviyero zvemhando yezvinhu zvekushandisa kune imwe media.Kune zvakare zviyero pamagumo ekubatanidza kana kukora kwesimbi yekushandisa kune valve.

Mitemo yakadaro inounza kuchengeteka kune zvikumbiro.Pane kazhinji kuwedzera kwekushisa uye kudzvinyirira paunenge uchishandisa throttling valves.Naizvozvi, zvakakosha kuti tinzwisise mitemo yakadai yekuchengeteka kwemunhu wese.

Muchidimbu

Nepo mavharuvhu mazhinji aine mashoma ekutambisa masimba, munhu haangoashandisa saizvozvo.Kuti valve igare kwenguva yakareba, zviri nani kuziva kuti ndeupi rudzi rwevhavha yakakodzera kune imwe throttling application.

Reference valve mugadziri sosi: The Ultimate Guide: Best Vagadziri Vagadziri muChina

Nguva yekutumira: Feb-25-2022